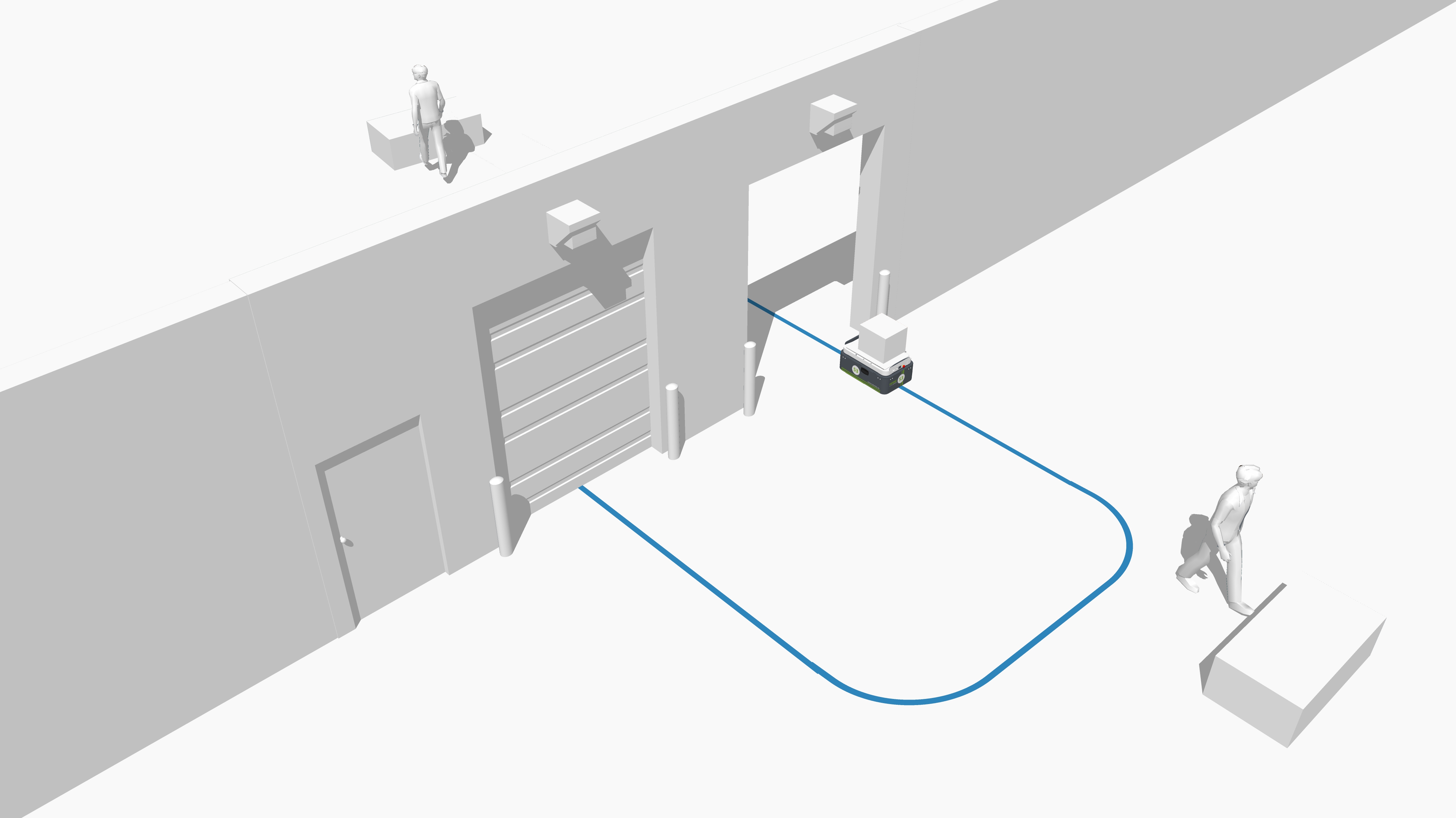

Area connection

In production environments, it is not uncommon for various work steps to be spatially separated due to larger machines with different requirements. In such cases, an AGV can be utilized to connect these distinct areas and, consequently, replace manual transport. When compared to continuous conveyor technology, an automated guided vehicle provides substantially greater flexibility and cost savings.

Station linking

In workshop of island production, various production steps are performed on a product at different stations. To transport partially assembled products to the next assembly station, station changing is employed. The use of an AGV is particularly well-suited for this purpose due to its high degree of flexibility, even with a relatively low throughput.