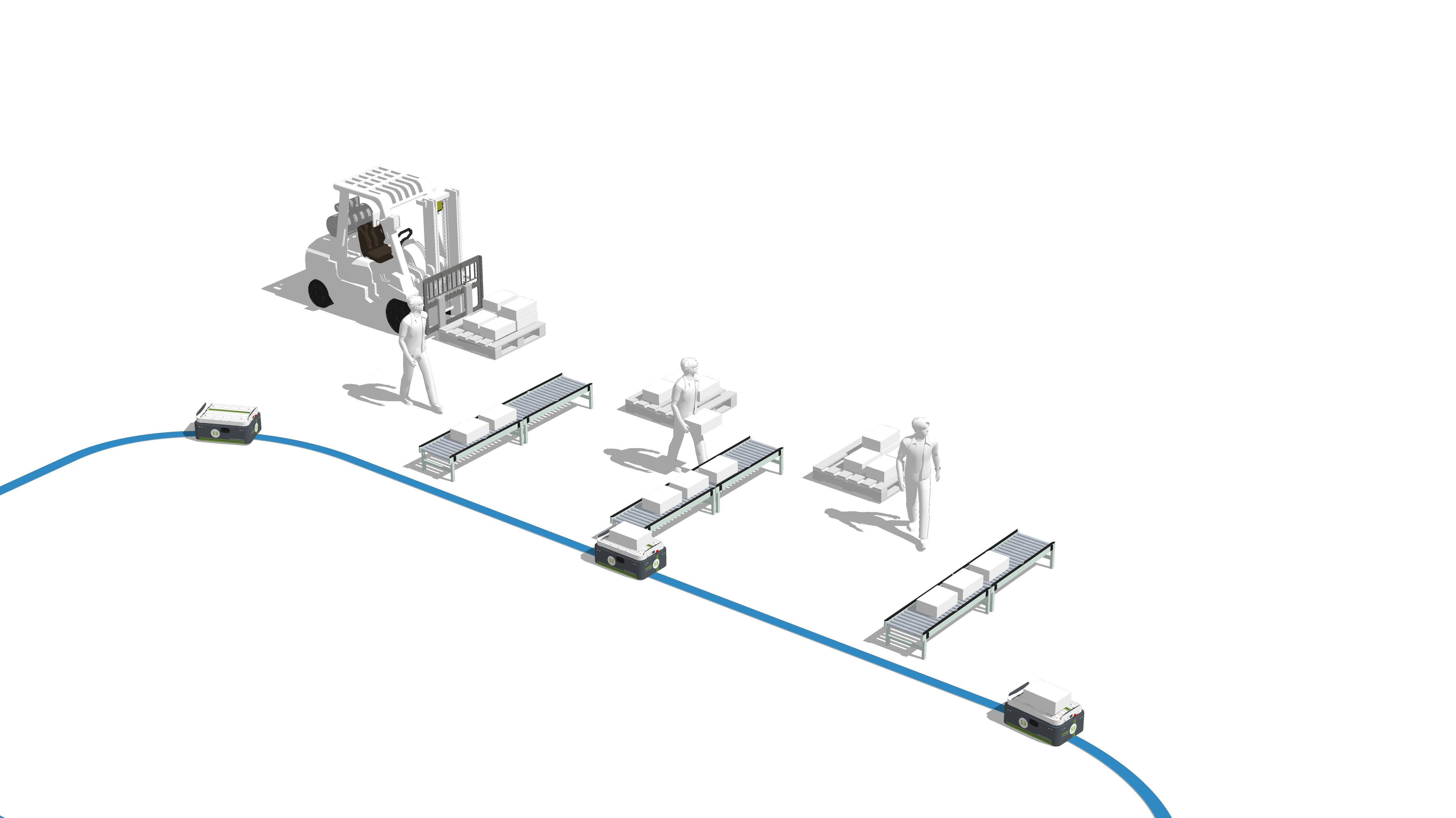

Incoming goods

The goods-receiving area typically serves as the initial point of interaction between goods and logistics. Therefore, optimizing the material flow here is crucial. Utilizing automated guided vehicles (AGVs) can ensure efficient transport to order picking, the warehouse, or a packing station.

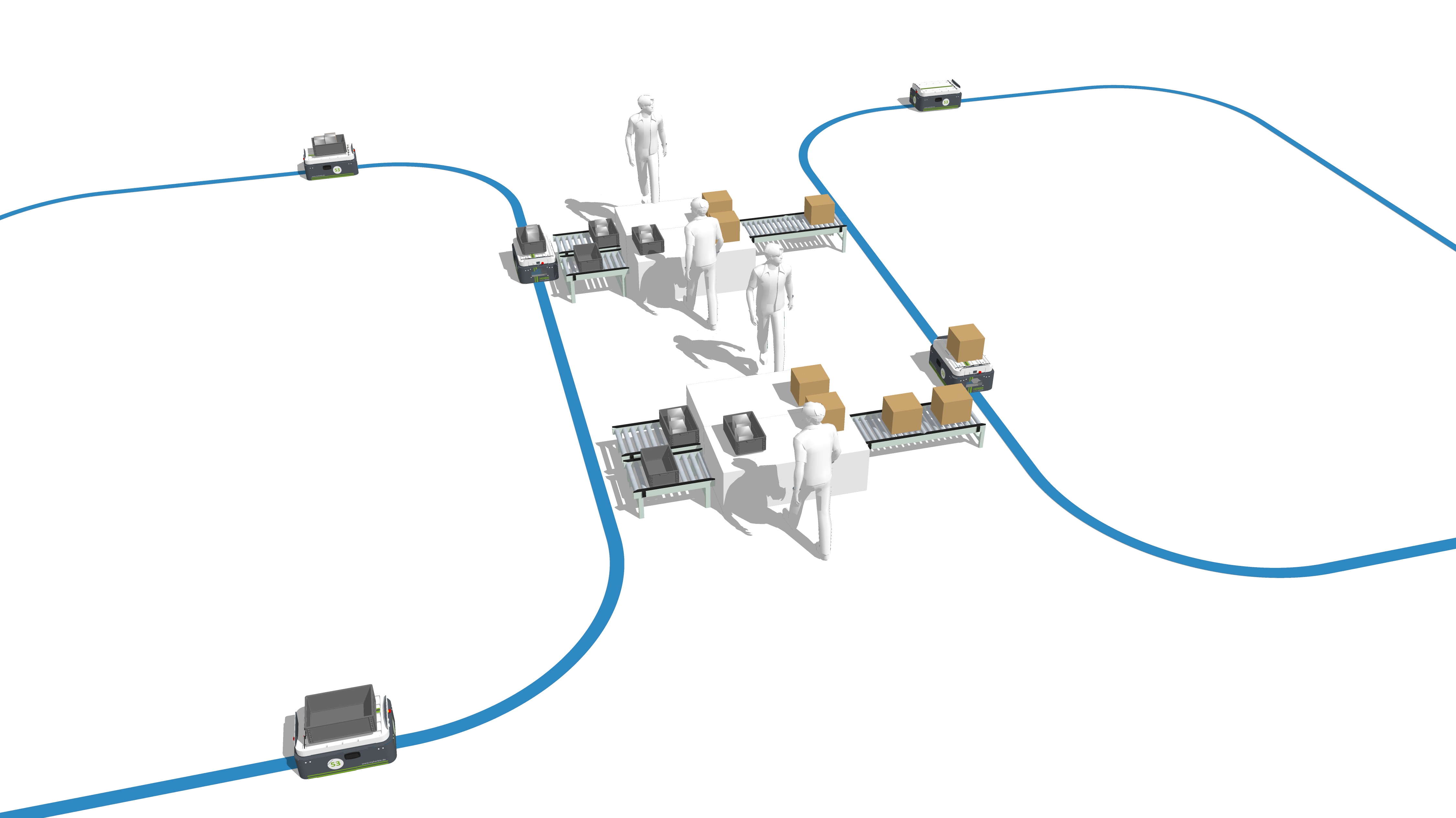

Picking

Order picking is a fundamental element of warehouse logistics and is very typically carried out using automated small-parts warehouses, Vertical Lift Modules (VLMs), or, traditionally, with order-picking trolleys. In all three scenarios, the use of AGVs is essential to automate the subsequent material flow. Whether the goods are destined for packing stations, the goods issue area, or production halls, AGVs play a crucial role in streamlining the process.

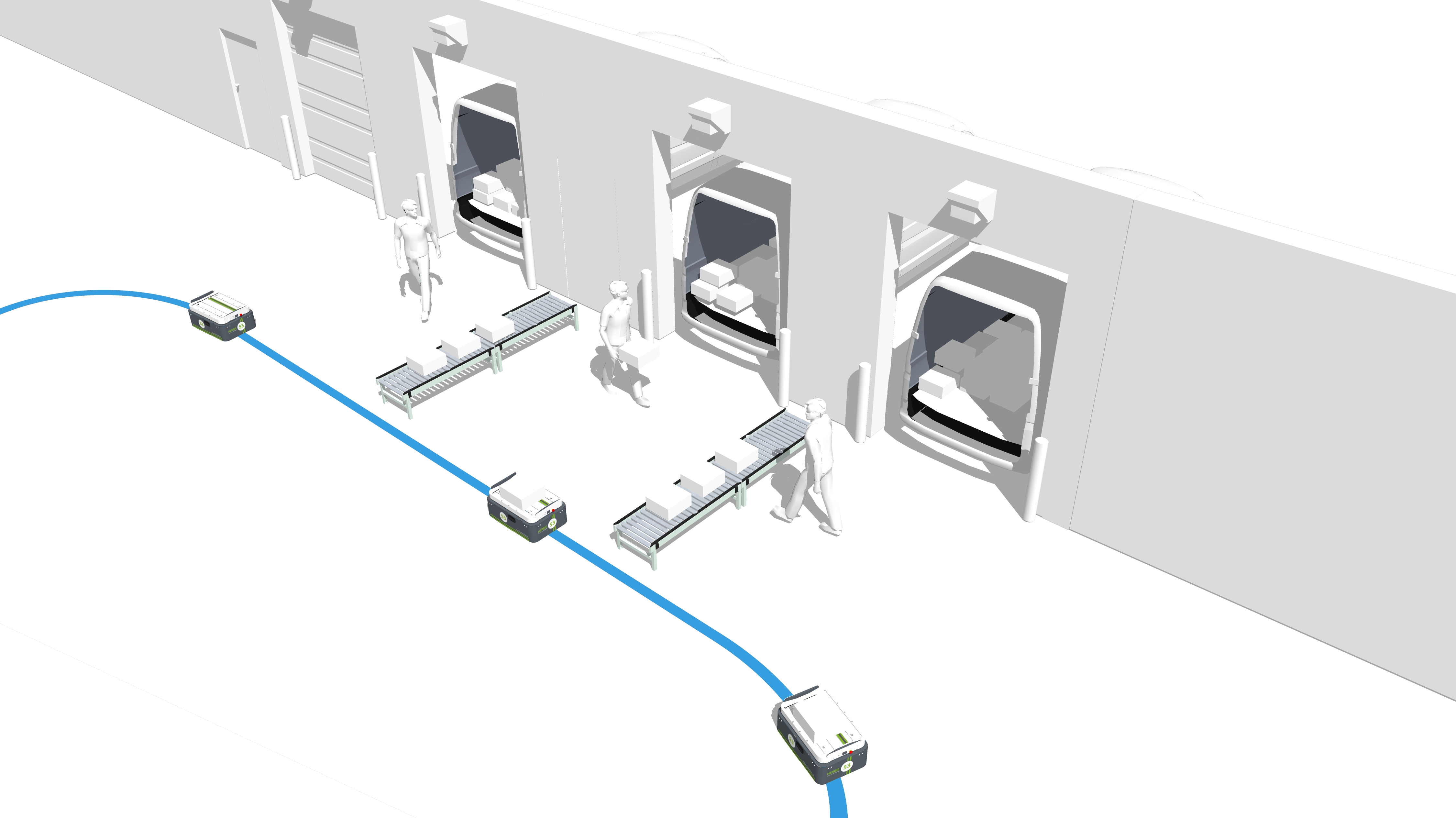

Packaging

Packing stations serve as a crucial intermediate step between warehouse/picking and the transportation of goods to end customers or distribution centres. Using an AGV, it is possible to establish two distinct material circuits to and from the packing station. Furthermore, accumulating roller conveyors can be integrated to smooth the throughput.

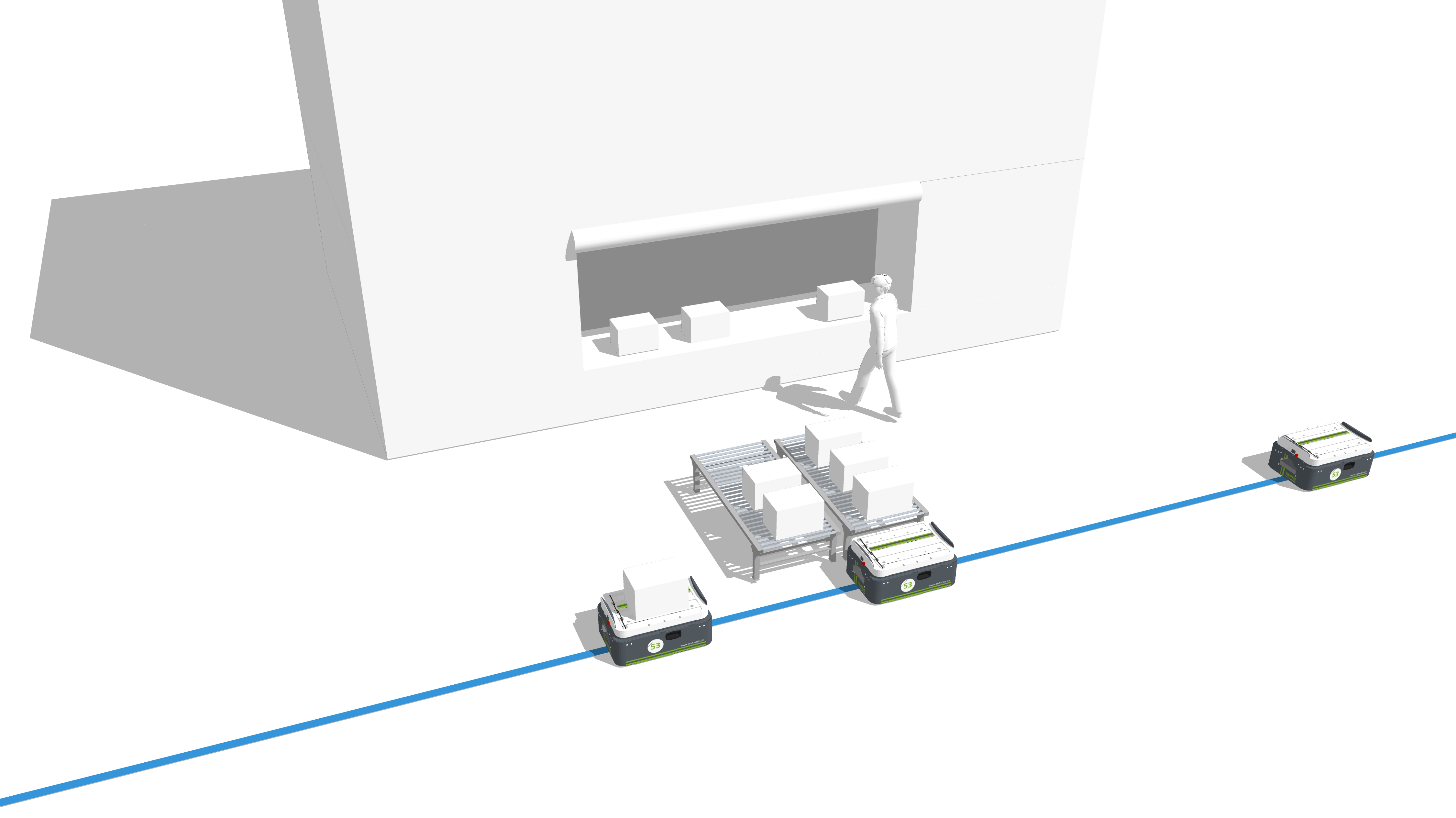

Outgoing goods

Much like the incoming goods area, the outgoing goods area serves as the interaction point between goods and the external world. Through the integration of accumulating roller conveyors, a direct connection to third-party logistics (TPL) at the goods issue area can be established, streamlining the preparation of goods for transportation to the end customer.